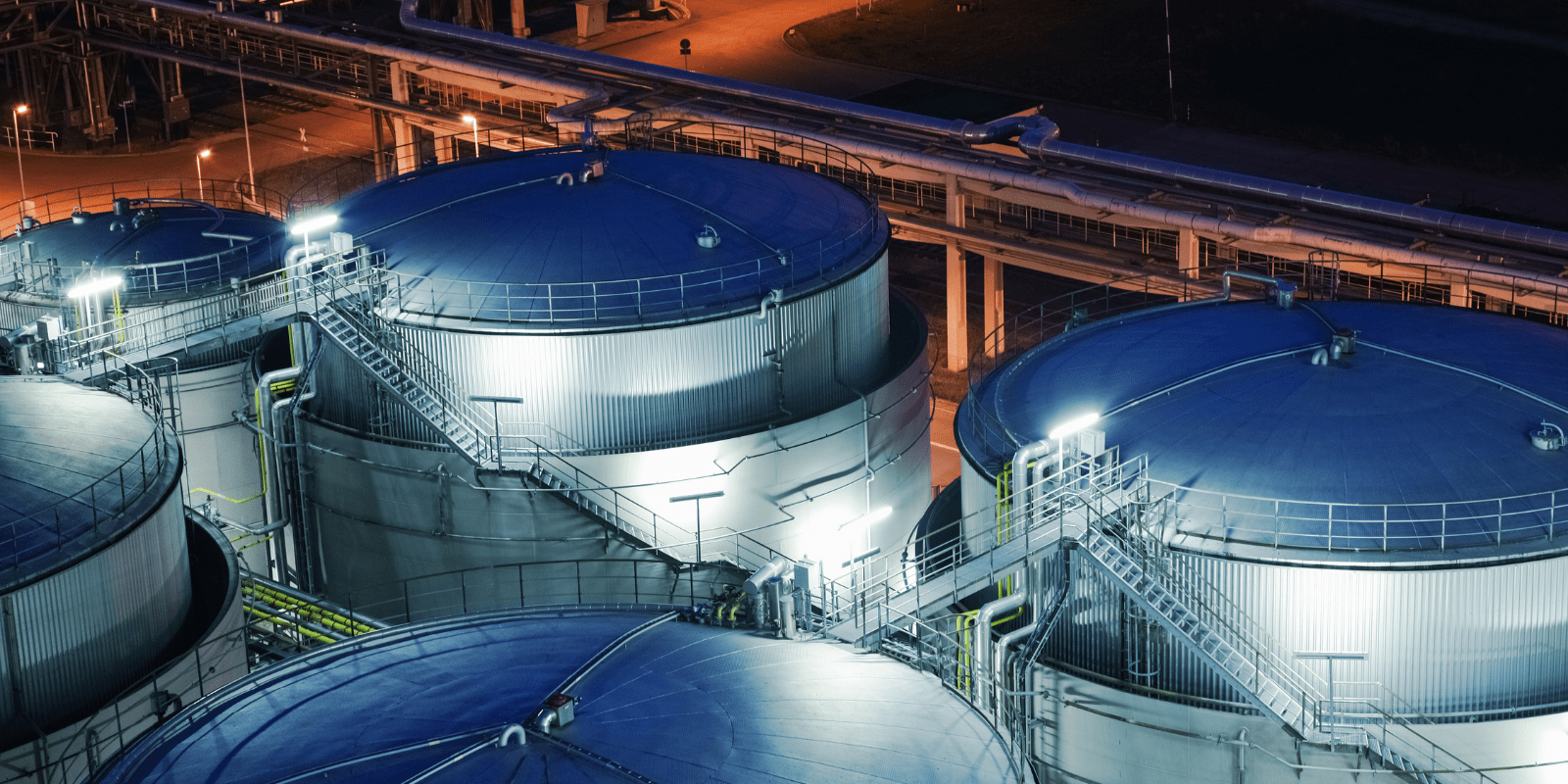

Asset Integrity Management

Ensure safe, reliable and efficient operations.

With asset integrity management (AIM) solutions from SGS, you will ensure that your asset can perform its required function effectively, whilst protecting health, safety and environment, throughout its entire lifecycle.

We offer bespoke AIM solutions for oil and gas refineries and plants, gas distribution units, fertiliser plants, chemical plants, power plants and pipelines. Our fully compliant program will provide you with reliable, safe and cost effective measures to keep your asset in fit-for-service condition.

Benefits of Asset Integrity Management

- Optimise asset value

- Maximise production

- Identify, monitor and mitigate risks in a timely manner

- Reduce revenue loss due to unplanned shutdowns

- Comply with regulatory and company requirements

Protect Your Assets

Our AIM solutions include non-destructive testing (NDT), risk-based inspections, health and condition assessments, corrosion studies and more.

Read the Brochure

Advanced Non-Destructive Testing

Non-destructive testing from SGS ensures the safe and efficient operation of your equipment and assets by detecting defects before they result in severe damage, and assures compliance with international standards. Our NDT services are integrated with our AIM solutions. We offer NDT methods such as:

- Ultrasonic testing

- Radiography testing

- Electromagnetic testing

- Magnetic flux leakage

- Leak testing

- Visual testing

- Penetrant testing

- Magnetic particle testing

Risk Based Inspection

RBI is a risk assessment and management process that is focused on loss of containment of pressurised equipment in processing facilities, due to material deterioration. Risks are managed primarily through equipment inspection.

RBI:

- Is carried out as per API 580/581 guidelines

- Is implemented with client software or SGS purchased software, i.e. GE Meridium, DNV, Orkosoft, Nexus, I2G

- Includes data management support and a full-time deployed inspector

- Includes preparation of inspection plan, based on API-580/581, with SGS in-house software

Benefits:

- Optimised inspection plan

- Increased plant availability owing to reduced shutdown duration and minimal unplanned shutdowns

- Reduction in costs associated with inspections

- Integrity safeguarding

Pipeline Integrity Management

Pipeline Integrity Management System (PIMS) software is used to manage pipeline integrity data. SGS India can provide a PIMS service using software that complies with API 1160.

Benefits:

- Sustainable operation of pipeline networks

- Reduction of unplanned shutdowns

- Minimisation of risks associated with pipeline operations

- Maximised productivity

- Cost optimisation

- Ability to predict remaining life of piping by determining corrosion rates

Residual Life Assessment

RLA is used to understand the current condition of the asset and determine whether equipment is functional and fit for purpose within the current application and during the anticipated extended operating life.

SGS’s RLA services include:

- Customised and cost-effective assessments

- Finite element analysis to assess equipment

- Solution based recommendations

- Identification of alternative service options, with enhanced equipment performance

- Recommendations for effective remediation and repair approaches

Fitness for Service Study

SGS provides customised and cost effective assessments of the FFS issues and challenges that are common in oil and gas, refining, pipeline, chemical, paper and pulp, and gas processing facilities. Software used for assessments has been developed and is supported by industry subject matter experts.

Benefits:

- Mitigate safety risks by performing rapid FFS Level 1 and Level 2

- Determine the size of flaws which would require repair or equipment replacement if found in future inspection

- Increases profitability by improving plant reliability and avoiding unplanned downtime

Minimise Risk

We detect defaults in your asset before they can cause severe damage.

Contact UsWhy SGS?

We are the world’s leading testing, inspection and certification company, providing specialised solutions to make your business faster, simpler and more efficient. Through our worldwide network of experts, we help you to make informed decisions and achieve the standards and certifications to demonstrate your expertise and give you a competitive edge.

Why choose non-destructive testing from SGS?

SGS offers you the most effective NDT methods to investigate the integrity of your equipment and assets. Our comprehensive range of NDT methods can help you:

- Monitor the integrity of your assets using intrusive or non-intrusive methods

- Detect defects and irregularities before they result in severe damage or non-compliance

- Save time and money through fast and effective testing of your assets and equipment at every stage of their lifespan – from manufacturing through on-site operation

- Ensure safe and reliable operation of your facilities

The Expertise, Experience and Resources to Provide You with World Leading Non-destructive Testing

With a worldwide reputation based on a proven track record, we are the complete, global non-destructive testing provider that you can trust.

Ask the Experts

Prefer to talk to a specialist?

Call +91 773 855 1460